INTRODUCTION

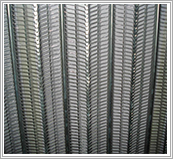

Rockmax Riblath is the most rigid of all metal laths. With full 3/8” ribs longitudinally spaced at 4” apart. This lath can be used both vertical and horizontal applications. It is designed to provide durable, effective for plastering and rendering work at job site. It is manufactured from pre-galvanised steel or stainless steel as per request.

AREA OF USES

Rockmax Riblath is ideal for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face. It can be use as the permanent construction joint for concrete slab if necessary designed. It can be use for internal or external applications.

ADVANTAGES

APPLICATION AND INSTALLATION

Fixing of Rib lath Sheets

Rib lath is fixed so that the tip of the rib is put against the supporting background. The rib of the sheet should run at right angles to any supports. Make sure that sheets are superposed by a minimum of 50mm end to end and by 25mm width ways and that the ribs are nestled together.

Wood Support

Rib lath is fixed at each rib to wood supports using plasterers’ nails or staples. Make sure that compatible corrosion resistant fixings are used, for example, please don’t use galvanized fixings for stainless steel.

Metal or Steel Support

Rib lath is fixed at each rib to metal support using 1.63mm galvanized or stainless steel tying wire. When joining rib lath sheets overlap the edge ribs and tie the edges with 1.22mm tying wire at 150mm centers.

Solid Background

Rib lath can be fixed to a solid background using a suitable fixing which holds the ribs firmly against the background. Where sheets are installed perpendicularly, fixings should be positioned through all ribs at 600mm centers to make sure there have enough stability. Movement joints should be provided at maximum 50mm center (vertically and horizontally) for render finishes.

STORAGE

Storage in shade and dry condition, Avoid from frost, water, moisture and high temperature.