INTRODUCTION

Rockmax PSseal is two component, low modulus polysulphide joint sealant. The cured material provides good bonding, elasticity, flexible and durable joint sealant. The material based on polysulphide polymer and selected additives. It is use for many application areas which requires high performance and chemical resistance & deterioration resistance sealant with exposure to direct UV environment.

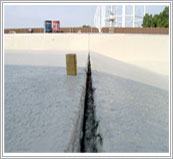

AREA OF USES

ADVANTAGES

APPLICATION AND INSTALLATION

PREPARATION

The joints must be clean and dry. Remove all dirt, dusts, cement pastes, oil, grease and other contaminants. Concrete substrate age must be minimum 4 weeks old. Make sure the joints are in good condition and good shape. The repair and structural sound of joint surface is required by mechanical mean. Joints edge must be straight and sharp. Damaged joints edge must be repair by epoxy mortar or consult Rockmax for further advice.

PRIMING

All concrete joints must be prime by Rockmax PS Primer. The primer must be applied by brush and allow until tack free prior to install backer rod and apply joint sealant. However if sealant is not apply after 4 hours, Re-prime surface again. Install guide tape both side of joints for proper finished. Other substrates such as steel, glass, ceramics etc. please consult Rockmax.

MIXING

The material supply in one container. The base and curing agent are store in the single pack. Use slow speed electric mixer (400-500rpm) for mixing the material. Mix for 4-6 minute until the product dispersed and uniform color and homogeneous. Do not mix by hand trowel or do not partial mix.

APPLICATION

Horizontal joint:

Pour the mixed material to the joints direct from container. Care should be taken during application. Finishing the surface of sealant using curve spatula or similar tools to make concave profile of sealants.

Vertical joint:

Pour the mixed material to barrel gun. Apply the sealant from bottom of joint and continuously apply. Finishing the surface of sealant using curve spatula or similar tools to make concave profile of sealants.

CURING

Curing time depend on ambient temperature. Full cure take at approximate 7 days. Protect the sealant from water, traffic and other contaminants.

PACKAGING

Gun grade: 2.5 litre/ container

Pour grade: 4.5 litre/ container